Functional Analysis

The following text is from the Delft Design Guide.

Daalhuizen, Jaap. 2018. Delft Design Approach, Delft University of Technology.

What Is a Function Analysis?

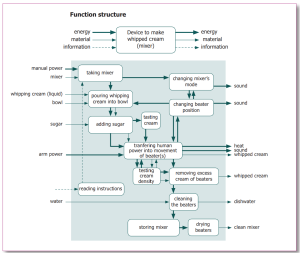

Function analysis is a method for analyzing and developing a function structure. A function structure is an abstract model of the new product, without material features such as shape, dimensions and materials of the parts. It describes the functions of the product and its parts and indicates the mutual relations. The underlying idea is that a function structure may be built up from a limited number of elementary (or general) functions on a high level of abstraction. Functions are abstractions of what a product should do. Being forced to think about the product in an abstract way stimulates creativity, and prevents you from ‘jumping to solutions’, i.e. immediately elaborating on the first idea that comes to mind, which may not be the best.

In function analysis, the product is considered as a technical-physical system. The product functions, because it consists of a number of parts and components which fulfil subfunctions and the overall function. By choosing the appropriate form and materials, a designer can influence the subfunctions and the overall function. The principle of function analysis is first to specify what the product should do, and then to infer from there what the parts – which are yet to be developed – should do. Function analysis forces designers to distance themselves from known products and components in considering the question: what is the new product intended to do and how could it do that? The method is useful to accomplish a breakthrough in thinking in conventional solutions.

A function analysis often precedes the morphological method (see ‘Morphological Chart’ in this section). The functions and subfunctions that are identified in the function analysis serve as the parameters in the morphological chart.

When Can You Use a Function Analysis?

A function analysis is typically carried out at the beginning of idea generation.

How to Use a Function Analysis?

Starting Points

There are two possible starting points, which may be used in a combined form:

- A process tree, which can be drafted from scratch or based on an existing solution of the design problem (or a comparable problem)

- A collection of elementary (general) functions, for instance the functional basis developed by the American National Institute of Standards and Technology (NIST).

Expected Outcome

The outcome of the function analysis is a thorough understanding of the functions and subfunctions that the new product has. From functions and subfunctions the parts and components for the new product can be developed, for instance by using them as input for the creation of a morphological chart.

Possible Procedure

- Describe the main function of the product in the form of a black box. If you cannot define one main function, go to the next step.

- Make a list of subfunctions. The use stage of a process tree is a good starting point. By adding extra columns to the process tree in which you distinguish between product functions and user tasks, you can make a first list of functions.

- Just like the processes in a process tree, functions are based on verb-noun combinations. Only those processes that are carried out by the product are functions; processes performed by the user are user tasks. For user tasks, you can often define functions that support the user in performing the task. For instance, for a user task lift product a supporting function would be provide grip for lifting.

- For a complex product, you may want to develop a function structure. There are three principles of structuring: putting functions in a chronological order, connecting inputs and outputs of flows between functions (matter, energy and information flows) and hierarchy (main functions, subfunctions, subsubfunctions, etc.). These principles cannot always be applied – see the last item of Tips and Concerns. To visualize the chronological order, you can simply list the functions. To visualize the flows, you can connect boxes by arrows. To visualize hierarchy, you can draw a tree structure (just like the process tree) so that you can combine hierarchy with chronological order, or you can draw boxes-in-boxes, so that you can combine hierarchy and flows in one diagram.

- Elaborate the function structure. Fit in a number of `auxiliary’ functions which were left out and find variations of the function structure so as to find the best function structure. Variation possibilities include moving the system boundary, changing the sequence of subfunctions and splitting or combining functions. Exploring various possibilities is the essence of function analysis: it allows for an exploration and generation of possible solutions to the design problem.

Tips and Concerns

- If you have a function structure, it is recommended you develop variants of it. A statement of a problem never leads imperatively to one particular function structure. The strength of function analysis lies in the possibility of creating and comparing, at an abstract level, alternatives for functions and their structuring.

- Certain subfunctions appear in almost all design problems. Knowledge of the elementary or general functions helps in seeking product-specific functions.

- The development of a function structure is an iterative process. There is nothing against starting by analysing an existing design or with a first outline of an idea for a new solution. However, in the course of the analysis you should abstract from it.

- Function structures should be kept as simple as possible. The integration of various functions into one component (function carrier) is often a useful means in this respect.

- Block diagrams of functions should remain conveniently arranged; use simple and informative symbols. Be aware of different types of functions.

- In industrial design engineering and product design, it is not always possible to apply structuring principles. The principles have their background in mechanical engineering, where functions describe machines processing raw materials in steps to produce products. Don’t worry: an unstructured list of (sub)functions is better than no function descriptions at all.

References and Further Reading

Roozenburg, N.F.M. and Eekels, J. (1995) Product Design: Fundamentals and Methods, Utrecht: Lemma.

Roozenburg, N. and Eekels, J. (1998, 2nd ed.) Product Ontwerpen: Structuur en Methoden, Utrecht: Lemma.

Cross, N. (1989) Engineering Design Methods, Chichester: Wiley.