Design Process Overview

In this course we will utilize a “systematic” description of the design process. There are several reasons for using this as a model but before getting into those justifications, it is important to note that there are actually many paradigms of engineering design. The way you perceive the design process affects how, when and what type of decisions you make. For an example of a very different paradigm from systematic design, look up C-K theory. Additionally, there are many different variations of the systematic process that help designers focus on one aspect or another. For example, User-Centered design is a popular paradigm that focuses designers’ empathy to satisfy the needs of users or customers.

So why are focusing on the systematic design process?

- The systematic process is what is most common in industrial practice.

- The systematic nature is conducive to the structure of an academic course with stages, assessments, and regular deliverables.

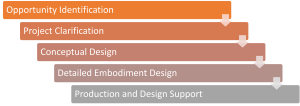

5 Stages of Product Design

At the most basic form, a systematic design process describes the process of moving between four phases:

- Opportunity Identification

- Project Clarification

- Conceptual Design

- Embodiment and Detail Design

- Design Support

Opportunity Identification

The first phase of product design is identifying and clarifying a project opportunity. This phase involves finding a problem or need that can be solved by designing a new or improved product. The problem or need may come from various sources, such as customers, competitors, market trends, regulations, or technological developments. The product designer must research the problem or need and define it clearly and precisely.

Identifying and clarifying a project opportunity also requires evaluating the feasibility and desirability of the potential product. The product designer must consider the technical, economic, social, and environmental aspects of the product and how they affect its performance, cost, quality, safety, and sustainability. This stage often also includes the identification of stakeholders. Stakeholders are those with an interest in the outcome of the design process. Those can include your company, government regulators, distribution and sales organizations, customers, users, maintenance personnel or organizations, and others depending on the domain. Failing to identify an important stakeholder at this stage can lead to making the wrong product for the wrong stakeholder.

Project Clarification

The second phase of engineering design is project clarification. In this phase, the engineer defines the problem and its scope more clearly by determining what these stakeholders need from the design, such as functionality, performance, reliability, safety, cost, aesthetics, etc. These needs are then prioritized and translated into measurable technical targets that can be used to evaluate and compare different design concepts in the next phase. Project clarification is a critical step in engineering design because it ensures that the design meets the expectations and requirements of the intended users and customers, as well as other social, environmental, ethical, and legal factors. The project clarification stage is when we define the evaluation criteria to assess if our design is successful. Successful designs are those that satisfy stakeholder needs by achieving the identified targets within economic, manufacturability, ethical and other constraints.

Conceptual Design

The third phase of engineering design is conceptual design. In this phase, the problem is defined by identifying the required functions. The functions are the actions or tasks that the product or system must perform to satisfy the customer needs and specifications.

Conceptual design involves generating one or more solution principles for each function. The next step of conceptual design is to select the concept for each function and combine them into an overall product or system concept. This synthesis step should be done several times in order to develop a large potential pool of complete concepts. Finally, these complete concepts can be evaluated and a single or few concepts can move forward towards detailed design. This evaluation is done by using various criteria such as stakeholder needs, design targets, concept screening, concept scoring, and decision matrices. The selected concept should meet or exceed the customer expectations and requirements, as well as be feasible, reliable, and cost-effective.

Embodiment and Detailed Design

The detailed stage of design is the fourth phase in the mechanical product design process, where the system architecture, assemblies and their arraignments are defined. This stage involves specifying the types of standard components and the material and geometry of custom-made components that will be used to realize the product functionality and performance. The Detailed stage of design requires careful analysis and evaluation of various design alternatives, trade-offs and constraints, as well as consideration of manufacturability, reliability, maintainability and cost aspects. The output of this stage is a complete set of detailed drawings, specifications and documentation that describe the product structure and characteristics.

Production and Support

The production and support stage is the fifth and final stage of product design. This stage involves defining the processes and methods for manufacturing and assembling the product. This may require testing and refining different prototypes until the product meets the desired specifications and quality standards. The production and support stage also includes providing ongoing maintenance and service for the product, as well as planning for its disposal or recycling at the end of its life cycle. This is important for minimizing the environmental impact of the product and promoting sustainability.